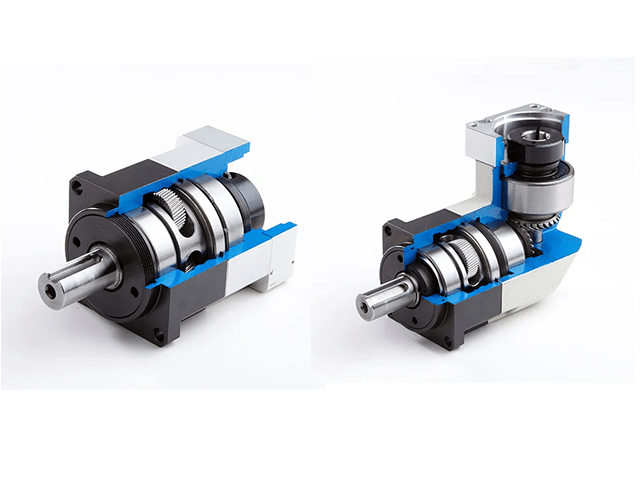

Planetary Gearheads

SPIH/SPLH SERIES

High torque & low backlash

- はすば歯車式遊星歯車装置です。

- ギヤ熱処理により耐摩耗性が向上。

Increased service life

- 総ころニードル遊星ベアリング。 (ソリッドアンケージ針状ころ軸受)

Dynamic balanced clamp ring mechanism

- エラーのない取り付けとバランスの取れたクランプ システムにより、入力速度が向上し、動力伝達のバックラッシュがなくなりました。

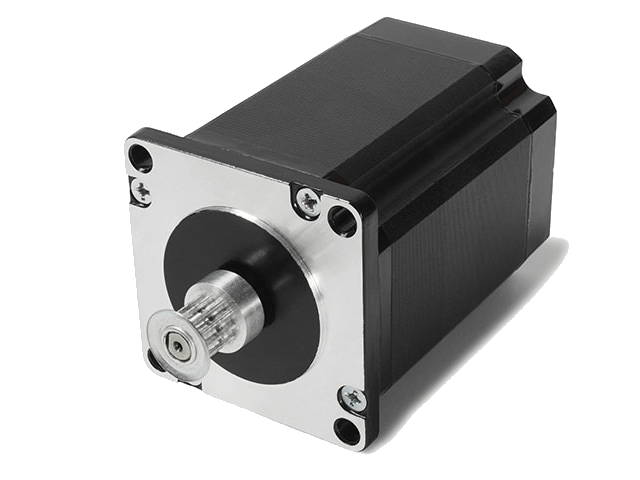

Universal mounting motor flange

- 短納期での納品が可能となり、ステッピングモーターやサーボモーターへの取り付けも容易になります。

Classifications

| Group | Figure | Series Name |

Frame Size |

*Ratio | |

| Helical Gear Type |

In-line |  |

SPIH | ☐42 ~ ☐220 | 1/3 ~ 1/10 |

| 1/15 ~ 1/100 | |||||

|

SPHI-D | ☐60 ~ ☐220 | 1/15 ~ 1/100 | ||

|

SPIFH | ☐42 ~ ☐220 | 1/4 ~ 1/10 | ||

| 1/16 ~ 1/100 | |||||

|

SPIFH-D | ☐60 ~ ☐220 | 1/16 ~ 1/100 | ||

| Right Angle |

|

SPLH | ☐42 ~ ☐220 | 1/3 ~ 1/20 (1/3 ~ 1/10) |

|

| 1/25 ~ 1/100 (1/15 ~ 1/100) |

|||||

|

SPLH-D | ☐60 ~ ☐220 | 1/25 ~ 1/100 | ||

|

SPLFH | ☐42 ~ ☐220 | 1/4 ~ 1/20 (1/4 ~ 1/10) |

||

| 1/25 ~ 1/100 (1/20 ~ 1/100) |

|||||

|

SPLFH-D | ☐60 ~ ☐220 | 1/25 ~ 1/100 | ||

| Spur Gear Type |

In-line |  |

SPI | ☐42 ~ ☐115 | 1/3 ~ 1/10 |

| 1/15 ~ 1/100 | |||||

|

SPI-D | ☐60 ~ ☐115 | 1/15 ~ 1/100 | ||

| Right Angle |

|

SPL | ☐42 ~ ☐115 | 1/3 ~ 1/20 (1/3 ~ 1/10) |

|

| 1/25 ~ 1/100 (1/15 ~ 1/100) |

|||||

|

SPL-D | ☐60 ~ ☐115 | 1/25 ~ 1/100 | ||

*Ratios in parenthesis are based on ☐42 model.

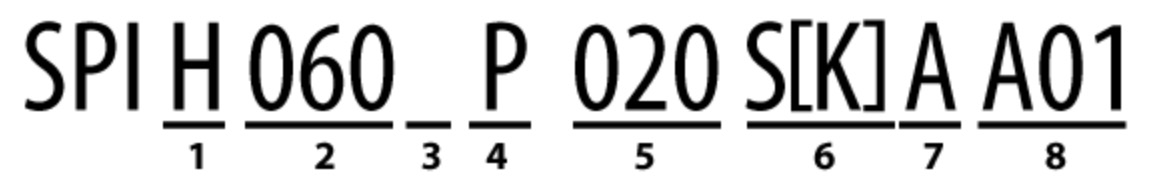

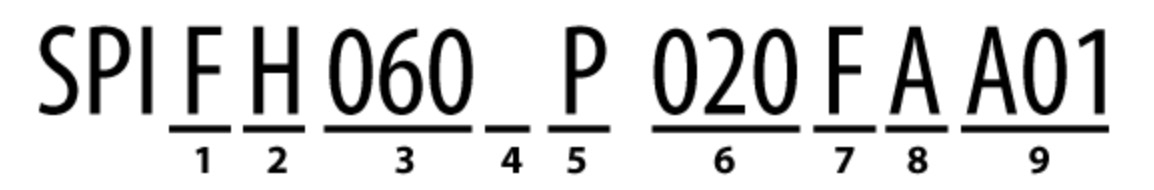

SPIH Specifications

| 1. Gear type | 2. Frame size | 3. Input frame size | 4. Backlash | |||||

| H | Helical | 042 |  40 40 |

No symbol | Standard | P | Precision Class |

1 Stage: ≤3 arcmin 2 Stage: ≤5 arcmin |

| 060 |  60 60 |

D | Down size* | S | Standard Class |

1 Stage: ≤5 arcmin 2 Stage: ≤7 arcmin |

||

| 090 |  90 90 |

|||||||

| 115 |  115 115 |

|||||||

| 142 |  142 142 |

|||||||

| 180 |  190 190 |

|||||||

| 220 |  220 220 |

|||||||

| 5. Gear ratio (i) | 6. Output shaft option | |||||||

| 1 stage | 2 Stage | S | Smooth output shaft | |||||

| 003 | 1/3 | 015 | 1/15 | K | Output shaft with key | |||

| 004 | 1/4 | 020 | 1/20 | |||||

| 005 | 1/5 | 025 | 1/25 | 7. Input adaptor flange (servo motors) | ||||

| 006 | 1/6 | 030 | 1/30 | A | Mitsubishi, Yaskawa, Tamagawa, HIGEN, LS Series | |||

| 007 | 1/7 | 035 | 1/35 | B | Panasonic Series | |||

| 008 | 1/8 | 040 | 1/40 | C | Rockwell Series | |||

| 009 | 1/9 | 045 | 1/45 | |||||

| 010 | 1/10 | 050 | 1/50 | 8. Special order code | ||||

| 060 | 1/60 | |||||||

| 070 | 1/70 | |||||||

| 080 | 1/80 | |||||||

| 090 | 1/90 | |||||||

| 100 | 1/100 | |||||||

*The input frame of down size depends on customer’s request

Specifications

| Description | Stage | Ratio (1) | Model No. | ||||||||||||

| SPIH 042 | SPIH 060 | SPIH 060D | SPIH 090 | SPIH 090D | SPIH 115 | SPIH 115D | SPIH 142 | SPIH 142D | SPIH 180 | SPIH 180D | SPIH 220 | SPIH 220D | |||

| Nominal Output torque T2N(2) | 1 | 3 | 16 | 48 | – | 117 | – | 195 | – | 480 | – | 750 | – | 1,600 | – |

| 4 | 16 | 36 | – | 107 | – | 215 | – | 635 | – | 950 | – | 1,600 | – | ||

| 5 | 19 | 43 | – | 120 | – | 250 | – | 580 | – | 1,200 | – | 2,080 | – | ||

| 6 | 15 | 43 | – | 107 | – | 215 | – | 530 | – | 1,100 | – | 1,630 | – | ||

| 7 | 15 | 40 | – | 100 | – | 213 | – | 495 | – | 980 | – | 1,960 | – | ||

| 8 | 10 | 43 | – | 106 | – | 220 | – | 420 | – | 870 | – | 1,700 | – | ||

| 9 | 14 | 35 | – | 93 | – | 160 | – | 390 | – | 710 | – | 1,560 | – | ||

| 10 | 11 | 30 | – | 94 | – | 215 | – | 370 | – | 790 | – | 1,395 | – | ||

| 2 | 15 | 16 | 48 | 48 | 117 | 117 | 195 | 195 | – | 480 | – | 750 | – | 1,600 | |

| 20 | 16 | 36 | 36 | 107 | 107 | 215 | 215 | – | 635 | – | 950 | – | 1,600 | ||

| 25 | 19 | 43 | 43 | 120 | 120 | 250 | 250 | – | 580 | – | 1,200 | – | 2,080 | ||

| 30 | 19 | 43 | 43 | 120 | 120 | 250 | 250 | – | 580 | – | 1,200 | – | 2,080 | ||

| 35 | 19 | 43 | 43 | 120 | 120 | 250 | 250 | – | 580 | – | 1,200 | – | 2,080 | ||

| 40 | 19 | 43 | 43 | 120 | 120 | 250 | 250 | – | 580 | – | 1,200 | – | 2,080 | ||

| 45 | 19 | 43 | 43 | 120 | 120 | 250 | 250 | – | 580 | – | 1,200 | – | 2,080 | ||

| 50 | 19 | 43 | 43 | 120 | 120 | 250 | 250 | – | 580 | – | 1,200 | – | 2,080 | ||

| 60 | 15 | 43 | 43 | 107 | 107 | 215 | 215 | – | 530 | – | 1,100 | – | 1,630 | ||

| 70 | 15 | 40 | 40 | 100 | 100 | 213 | 213 | – | 495 | – | 980 | – | 1,960 | ||

| 80 | 10 | 43 | 43 | 106 | 106 | 220 | 220 | – | 420 | – | 870 | – | 1,700 | ||

| 90 | 14 | 35 | 35 | 93 | 93 | 160 | 160 | – | 390 | – | 710 | – | 1,560 | ||

| 100 | 11 | 30 | 30 | 94 | 94 | 215 | 215 | – | 370 | – | 790 | – | 1,395 | ||

| Max Acceleration torque T2B | 1,2 | 3~100 | 3 Times of Nominal Output Torque | ||||||||||||

| Backlash (Standard Class) |

1 | 3~10 | ≤ 5 | ≤ 5 | – | ≤ 5 | – | ≤ 5 | – | ≤5 | – | ≤5 | – | ≤5 | – |

| 2 | 15~100 | ≤ 7 | ≤ 7 | ≤ 7 | ≤ 7 | ≤ 7 | ≤ 7 | ≤ 7 | – | ≤7 | – | ≤7 | – | ≤7 | |

| Backlash (Precision Class) |

1 | 3~10 | ≤ 3 | ≤ 3 | – | ≤ 3 | – | ≤ 3 | – | ≤ 3 | – | ≤ 3 | – | ≤3 | – |

| 2 | 15~100 | ≤ 5 | ≤ 5 | ≤ 5 | ≤ 5 | ≤ 5 | ≤ 5 | ≤ 5 | – | ≤ 5 | – | ≤ 5 | – | ≤5 | |

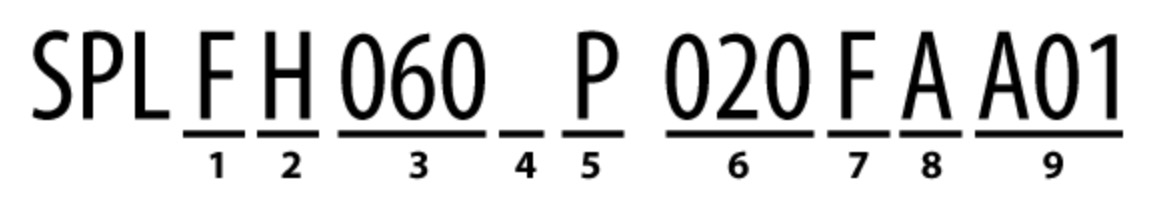

SPIFH Specifications

| 1. Type | 3. Frame size | 4. Input frame size | 5. Backlash | |||||

| F | Flange | 042 |  40 40 |

No symbol | Standard | P | Precision Class |

1 Stage: ≤3 arcmin 2 Stage: ≤5 arcmin |

| 060 |  60 60 |

D | Down size* | S | Standard Class |

1 Stage: ≤5 arcmin 2 Stage: ≤7 arcmin |

||

| 2. Gear type | 090 |  90 90 |

||||||

| H | Hellical | 115 |  115 115 |

|||||

| 142 |  142 142 |

|||||||

| 180 |  190 190 |

|||||||

| 220 |  220 220 |

|||||||

| 6. Gear ratio (i) | 7. Output shaft option | |||||||

| 1 stage | 2 Stage | F | Flange shaft | |||||

| 004 | 1/4 | 016 | 1/16 | |||||

| 005 | 1/5 | 020 | 1/20 | |||||

| 006 | 1/6 | 025 | 1/25 | 8. Input adaptor flange (servo motors) | ||||

| 007 | 1/7 | 035 | 1/35 | A | Mitsubishi, Yaskawa, Tamagawa, HIGEN, LS Series | |||

| 010 | 1/10 | 040 | 1/40 | B | Panasonic Series | |||

| 050 | 1/50 | C | Rockwell Series | |||||

| 070 | 1/70 | |||||||

| 100 | 1/100 | 9. Special order code | ||||||

*The input frame of down size depends on customer’s request

Specifications

| Description | Unit | Stage | Ratio (1) | Model No. | ||||||||||||

| SPIFH 042 | SPIFH 060 | SPIFH 060D | SPIFH 090 | SPIFH 090D | SPIFH 115 | SPIFH 115D | SPIFH 142 | SPIFH 142D | SPIFH 180 | SPIFH 180D | SPIFH 220 | SPIFH 220D | ||||

| Nominal Output torque T2N (2) | Nm | 1 | 4 | 16 | 36 | – | 107 | – | 215 | – | 540 | – | 950 | – | 1,600 | – |

| 5 | 19 | 43 | – | 120 | – | 250 | – | 590 | – | 1,200 | – | 2,080 | – | |||

| 7 | 15 | 40 | – | 100 | – | 213 | – | 530 | – | 980 | – | 1,960 | – | |||

| 10 | 11 | 30 | – | 94 | – | 215 | – | 420 | – | 790 | – | 1,395 | – | |||

| 2 | 16 | 16 | 36 | 36 | 107 | 107 | 215 | 215 | – | 540 | – | 950 | – | 1,600 | ||

| 20 | 16 | 36 | 36 | 107 | 107 | 215 | 215 | – | 540 | – | 950 | – | 1,600 | |||

| 25 | 19 | 43 | 43 | 120 | 120 | 250 | 250 | – | 590 | – | 1,200 | – | 2,080 | |||

| 35 | 19 | 43 | 43 | 120 | 120 | 250 | 250 | – | 590 | – | 1,200 | – | 2,080 | |||

| 40 | 19 | 43 | 43 | 120 | 120 | 250 | 250 | – | 590 | – | 950 | – | 2,080 | |||

| 50 | 19 | 43 | 43 | 120 | 120 | 250 | 250 | – | 590 | – | 1,200 | – | 2,080 | |||

| 70 | 15 | 40 | 40 | 100 | 100 | 213 | 213 | – | 530 | – | 980 | – | 1,960 | |||

| 100 | 11 | 30 | 30 | 94 | 94 | 215 | 215 | – | 420 | – | 790 | – | 1,395 | |||

| Max Acceleration torque T2B |

Nm | 1,2 | 4~100 | 3 Times of Nominal Output Torque | ||||||||||||

| Nominal Input speed n1 |

rpm | 1,2 | 4~100 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 |

| Max. Input speed N1 |

rpm | 1,2 | 4~100 | 6,000 | 6,000 | 6,000 | 5,000 | 5,000 | 5,000 | 5,000 | 5,000 | 5,000 | 5,000 | 5,000 | 5,000 | 5,000 |

| Backlash (Standard Class) | arcmin | 1 | 4~10 | ≤ 5 | ≤ 5 | – | ≤ 5 | – | ≤ 5 | – | ≤5 | – | ≤5 | – | ≤5 | – |

| 2 | 16~100 | ≤ 7 | ≤ 7 | ≤ 7 | ≤ 7 | ≤ 7 | ≤ 7 | ≤ 7 | – | ≤7 | – | ≤7 | – | ≤7 | ||

| Backlash (Precision Class) | arcmin | 1 | 4~10 | ≤ 3 | ≤ 3 | – | ≤ 3 | – | ≤ 3 | – | ≤ 3 | – | ≤ 3 | – | ≤3 | – |

| 2 | 16~100 | ≤ 5 | ≤ 5 | ≤ 5 | ≤ 5 | ≤ 5 | ≤ 5 | ≤ 5 | – | ≤ 5 | – | ≤ 5 | – | ≤5 | ||

| Torsional Rigidity |

Nm/arcmin | 1,2 | 4~100 | 2 | 3 | 3 | 12 | 12 | 23 | 23 | 38 | 38 | 110 | 110 | 210 | 210 |

| Max. Bending moment Mmax (2) |

Nm | 1,2 | 4~100 | 41 | 123 | 123 | 241 | 241 | 417 | 417 | 247 | 247 | 719 | 719 | 1,188 | 1,188 |

| Max. Axial load Fa max (2) |

Nm | 1,2 | 4~100 | 1,050 | 2,140 | 2,140 | 2,750 | 2,750 | 5,230 | 5,230 | 6,370 | 6,370 | 9,880 | 9,880 | 12,830 | 12,830 |

| service life (2) |

hr | 1,2 | 4~100 | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 |

| Noise level (3) |

dB(A) | 1,2 | 4~100 | ≤ 56 | ≤ 58 | ≤ 58 | ≤ 60 | ≤ 60 | ≤ 63 | ≤ 63 | ≤ 65 | ≤ 65 | ≤ 67 | ≤ 67 | ≤ 70 | ≤ 70 |

| Weight | kg | 1 | 4~10 | 0.7 | 1.4 | – | 4 | – | 8.5 | – | 18.1 | – | 48.1 | – | 85.4 | – |

| 2 | 16~100 | 0.9 | 1.9 | 1.5 | 5.5 | 4.4 | 12.3 | 9.6 | – | 24.2 | – | 56.2 | – | 107.2 | ||

| Mass Moments of Inertia (4) |

kg cm2 | 1 | 4~10 | 0.04 | 0.15 | – | 0.8 | – | 2.8 | – | 11.9 | – | 23.5 | – | 54 | – |

| 2 | 16~100 | 0.03 | 0.07 | 0.07 | 0.5 | 0.5 | 1.5 | 1.5 | – | 5.1 | – | 8.03 | – | 23.5 | ||

| Operating Temp. (5) |

℃ | 1,2 | 4~100 | -10 ~ +90 | ||||||||||||

| Lubrication | – | 1,2 | 4~100 | High temperature & Extreme pressure grease | ||||||||||||

| Mounting position |

– | 1,2 | 4~100 | All directions | ||||||||||||

| Efficiency η | % | 1 | 4~10 | ≥ 97 | ||||||||||||

| 2 | 16~100 | ≥ 94 | ||||||||||||||

| Degree of protection |

– | 1,2 | 4~100 | IP 65 | ||||||||||||

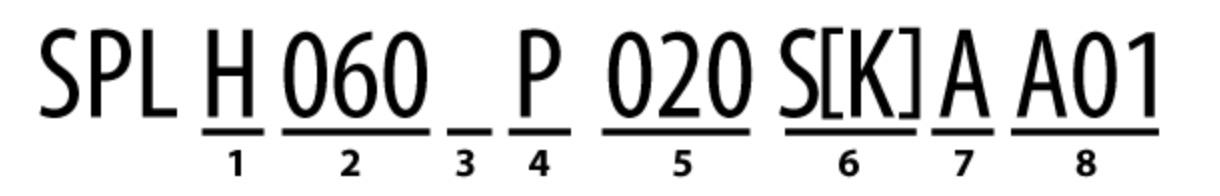

SPLH Specifications

| 1. Gear type | 2. Frame size | 3. Input frame size | 4. Backlash | |||||

| H | Helical | 042 |  40 40 |

No symbol | Standard | P | Precision Class |

1 Stage: ≤5 arcmin 2 Stage: ≤8 arcmin |

| 060 |  60 60 |

D | Down size* | S | Standard Class |

1 Stage: ≤7 arcmin 2 Stage: ≤10 arcmin |

||

| 090 |  90 90 |

|||||||

| 115 |  115 115 |

|||||||

| 142 |  142 142 |

|||||||

| 180 |  190 190 |

|||||||

| 220 |  220 220 |

|||||||

| 5. Gear ratio (i) | 6. Output shaft option | |||||||

| 1 stage | 2 Stage | S | Smooth output shaft | |||||

| 003 | 1/3 | (015) | (1/15) | K | Output shaft with key | |||

| 004 | 1/4 | (020) | (1/20) | |||||

| 005 | 1/5 | 025 | 1/25 | 7. Input adaptor flange (servo motors) | ||||

| 006 | 1/6 | 030 | 1/30 | A | Mitsubishi, Yaskawa, Tamagawa, HIGEN, LS Series | |||

| 007 | 1/7 | 035 | 1/35 | B | Panasonic Series | |||

| 008 | 1/8 | 040 | 1/40 | C | Rockwell Series | |||

| 009 | 1/9 | 045 | 1/45 | |||||

| 010 | 1/10 | 050 | 1/50 | 8. Special order code | ||||

| 014 | 1/14 | 060 | 1/60 | |||||

| 020 | 1/20 | 070 | 1/70 | |||||

| 080 | 1/80 | |||||||

| 090 | 1/90 | |||||||

| 100 | 1/100 | |||||||

*The input frame of down size depends on customer’s request

Specifications

| Description | Unit | Stage | Ratio (1) | Model No. | ||||||||||||

| SPLH 042 | SPLH 060 | SPLH 060D | SPLH 090 | SPLH 090D | SPLH 115 | SPLH 115D | SPLH 142 | SPLH 142D | SPLH 180 | SPLH 180D | SPLH 220 | SPLH 220D | ||||

| Nominal Output torque T2N (2) | Nm | 1 | 3 | 7.5 | 13.5 | – | 78 | – | 171 | – | 333 | – | 540 | – | 810 | – |

| 4 | 10 | 18 | – | 107 | – | 215 | – | 489 | – | 720 | – | 1,080 | – | |||

| 5 | 12.5 | 22.5 | – | 120 | – | 250 | – | 580 | – | 900 | – | 1,350 | – | |||

| 6 | 15 | 27 | – | 107 | – | 215 | – | 530 | – | 1,100 | – | 1,630 | – | |||

| 7 | 15 | 31.5 | – | 100 | – | 213 | – | 495 | – | 980 | – | 1,960 | – | |||

| 8 | 10 | 36 | – | 106 | – | 220 | – | 420 | – | 870 | – | 1,700 | – | |||

| 9 | 14 | 35 | – | 93 | – | 160 | – | 390 | – | 710 | – | 1,560 | – | |||

| 10 | 11 | 30 | – | 94 | – | 215 | – | 370 | – | 790 | – | 1,395 | – | |||

| 14 | – | 31.5 | – | 100 | – | 213 | – | 495 | – | 980 | – | 1,960 | – | |||

| 20 | – | 30 | – | 94 | – | 215 | – | 370 | – | 790 | – | 1,395 | – | |||

| 2 | 15 | 16 | – | – | – | – | – | – | – | – | – | – | – | – | ||

| 20 | 16 | – | – | – | – | – | – | – | – | – | – | – | – | |||

| 25 | 19 | 43 | 43 | 120 | 120 | 250 | 250 | – | 580 | – | 1,200 | – | 2,080 | |||

| 30 | 19 | 43 | 43 | 120 | 120 | 250 | 250 | – | 580 | – | 1,200 | – | 2,080 | |||

| 35 | 19 | 43 | 43 | 120 | 120 | 250 | 250 | – | 580 | – | 1,200 | – | 2,080 | |||

| 40 | 19 | 43 | 43 | 120 | 120 | 250 | 250 | – | 580 | – | 1,200 | – | 2,080 | |||

| 45 | 19 | 43 | 43 | 120 | 120 | 250 | 250 | – | 580 | – | 1,200 | – | 2,080 | |||

| 50 | 19 | 43 | 43 | 120 | 120 | 250 | 250 | – | 580 | – | 1,200 | – | 2,080 | |||

| 60 | 15 | 43 | 43 | 107 | 107 | 215 | 215 | – | 530 | – | 1,100 | – | 1,630 | |||

| 70 | 15 | 40 | 40 | 100 | 100 | 213 | 213 | – | 495 | – | 980 | – | 1,960 | |||

| 80 | 10 | 43 | 43 | 106 | 106 | 220 | 220 | – | 420 | – | 870 | – | 1,700 | |||

| 90 | 14 | 35 | 35 | 93 | 93 | 160 | 160 | – | 390 | – | 710 | – | 1,560 | |||

| 100 | 11 | 30 | 30 | 94 | 94 | 215 | 215 | – | 370 | – | 790 | – | 1,395 | |||

| Max Acceleration torque T2B |

Nm | 1,2 | 3~100 | 3 Times of Nominal Output Torque | ||||||||||||

| Nominal Input speed n1 |

rpm | 1,2 | 3~100 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 |

| Max. Input speed N1 |

rpm | 1,2 | 3~100 | 6,000 | 6,000 | 6,000 | 5,000 | 5,000 | 5,000 | 5,000 | 5,000 | 5,000 | 5,000 | 5,000 | 5,000 | 5,000 |

| Backlash (Standard Class) | arcmin | 1 | 3~20 | ≤ 7 | ≤ 7 | – | ≤ 7 | – | ≤ 7 | – | ≤ 7 | – | ≤ 7 | – | ≤ 7 | – |

| 2 | 15~100 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | – | ≤ 10 | – | ≤ 10 | – | ≤ 10 | ||

| Backlash (Precision Class) | arcmin | 1 | 3~20 | ≤ 5 | ≤ 5 | – | ≤ 5 | – | ≤ 5 | – | ≤ 5 | – | ≤ 5 | – | ≤ 5 | – |

| 2 | 25~100 | ≤ 8 | ≤ 8 | ≤ 8 | ≤ 8 | ≤ 8 | ≤ 8 | ≤ 8 | – | ≤ 8 | – | ≤ 8 | – | ≤ 8 | ||

| Torsional Rigidity |

Nm/arcmin | 1,2 | 3~100 | 2 | 3 | 3 | 12 | 12 | 23 | 23 | 38 | 38 | 110 | 110 | 210 | 210 |

| Max. Radial load Fr max (2) |

N | 1,2 | 3~100 | 400 | 1,100 | 1,100 | 2,400 | 2,400 | 4,000 | 4,000 | 8,000 | 8,000 | 13,000 | 13,000 | 18,600 | 18,600 |

| Max. Axial load Fa max (2) |

N | 1,2 | 3~100 | 300 | 600 | 600 | 1,800 | 1,800 | 2,500 | 2,500 | 3,000 | 3,000 | 6,000 | 6,000 | 11,300 | 11,300 |

| service life (2) |

hr | 1,2 | 3~100 | 20,000 | 20,000 | 20,000 | 20,000 | 20,000 | 20,000 | 20,000 | 20,000 | 20,000 | 20,000 | 20,000 | 20,000 | 20,000 |

| Noise level (3) |

dB(A) | 1,2 | 3~100 | ≤ 61 | ≤ 63 | ≤ 63 | ≤ 65 | ≤ 65 | ≤ 68 | ≤ 68 | ≤ 70 | ≤ 70 | ≤ 72 | ≤ 72 | ≤ 74 | ≤ 74 |

| Weight | kg | 1 | 3~20 | 0.9 | 2 | – | 5.7 | – | 12.9 | – | 22 | – | 46.4 | – | 77 | – |

| 2 | 25~100 | 1.1 | 2.4 | 2 | 7 | 5.9 | 16.7 | 14.1 | – | 24.8 | – | 50 | – | 88.2 | ||

| Mass Moments of inertia (4) |

kg cm2 | 1 | 3~20 | 0.04 | 0.15 | – | 0.8 | – | 2.8 | – | 11.9 | – | 23.5 | – | 54 | – |

| 2 | 25~100 | 0.03 | 0.07 | 0.07 | 0.5 | 0.5 | 1.5 | 1.5 | – | 5.1 | – | 8.03 | – | 23.5 | ||

| Operating Temp. (5) |

℃ | 1,2 | 3~100 | -10 ~ +90 | ||||||||||||

| Lubrication | – | 1,2 | 3~100 | High temperature & Extreme pressure grease | ||||||||||||

| Mounting position |

– | 1,2 | 3~100 | All directions | ||||||||||||

| Efficiency η | % | 1 | 3~20 | ≥ 95 | ||||||||||||

| 2 | 25~100 | ≥ 92 | ||||||||||||||

| Degree of protection |

– | 1,2 | 3~100 | IP 65 | ||||||||||||

SPLFH Specifications

| 1. Type | 3. Frame size | 4. Input frame size | 5. Backlash | |||||

| F | Flange | 042 |  40 40 |

No symbol | Standard | P | Precision Class |

1 Stage: ≤5 arcmin 2 Stage: ≤8 arcmin |

| 060 |  60 60 |

D | Down size* | S | Standard Class |

1 Stage: ≤7 arcmin 2 Stage: ≤10 arcmin |

||

| 2. Gear type | 090 |  90 90 |

||||||

| H | Hellical | 115 |  115 115 |

|||||

| 142 |  142 142 |

|||||||

| 180 |  190 190 |

|||||||

| 220 |  220 220 |

|||||||

| 6. Gear ratio (i) | 7. Output shaft option | |||||||

| 1 stage | 2 Stage | F | Flange shaft | |||||

| 004 | 1/4 | (020) | (1/20) | |||||

| 005 | 1/5 | 025 | 1/25 | |||||

| 007 | 1/7 | 035 | 1/35 | 8. Input adaptor flange (servo motors) | ||||

| 010 | 1/10 | 040 | 1/40 | A | Mitsubishi, Yaskawa, Tamagawa, HIGEN, LS Series | |||

| 014 | 1/14 | 050 | 1/50 | B | Panasonic Series | |||

| 020 | 1/20 | 070 | 1/70 | C | Rockwell Series | |||

| 100 | 1/100 | |||||||

| 9. Special order code | ||||||||

*The input frame of down size depends on customer’s request

Specifications

| Description | Unit | Stage | Ratio (1) | Model No. | ||||||||||||

| SPLFH 042 | SPLFH 060 | SPLFH 060D | SPLFH 090 | SPLFH 090D | SPLFH 115 | SPLFH 115D | SPLFH 142 | SPLFH 142D | SPLFH 180 | SPLFH 180D | SPLFH 220 | SPLFH 220D | ||||

| Nominal Output torque T2N (2) | Nm | 1 | 4 | 10 | 18 | – | 76 | – | 205 | – | 489 | – | 720 | – | 1,080 | – |

| 5 | 12.5 | 22.5 | – | 95 | – | 235 | – | 580 | – | 900 | – | 1,350 | – | |||

| 7 | 14 | 31.5 | – | 100 | – | 210 | – | 495 | – | 900 | – | 1,872 | – | |||

| 10 | 11 | 30 | – | 94 | – | 215 | – | 420 | – | 790 | – | 1,395 | – | |||

| 14 | – | 31.5 | – | 100 | – | 210 | – | 505 | – | 980 | 1,872 | |||||

| 20 | – | 30 | – | 94 | – | 215 | – | 370 | – | 790 | 1,395 | |||||

| 2 | 20 | 16 | – | – | – | – | – | – | – | – | – | – | – | – | ||

| 25 | 19 | 43 | 43 | 120 | 120 | 250 | 250 | – | 590 | – | 1,200 | – | 2,080 | |||

| 35 | 19 | 43 | 43 | 120 | 120 | 250 | 250 | – | 590 | – | 1,200 | – | 2,080 | |||

| 40 | 19 | 43 | 43 | 120 | 120 | 250 | 250 | – | 590 | – | 1,200 | – | 2,080 | |||

| 50 | 19 | 43 | 43 | 120 | 120 | 250 | 250 | – | 590 | – | 1,200 | – | 2,080 | |||

| 70 | 15 | 40 | 40 | 100 | 100 | 213 | 213 | – | 530 | – | 980 | – | 1,960 | |||

| 100 | 11 | 30 | 30 | 94 | 94 | 215 | 215 | – | 420 | – | 790 | – | 1,395 | |||

| Max Acceleration torque T2B |

Nm | 1,2 | 4~100 | 3 times of Nominal Output Torque | ||||||||||||

| Nominal Input speed n1 |

rpm | 1,2 | 4~100 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 |

| Max. Input speed N1 |

rpm | 1,2 | 4~100 | 6,000 | 6,000 | 6,000 | 5,000 | 5,000 | 5,000 | 5,000 | 5,000 | 5,000 | 5,000 | 5,000 | 5,000 | 5,000 |

| Backlash (Standard Class) | arcmin | 1 | 4~20 | ≤ 7 | ≤ 7 | – | ≤ 7 | – | ≤ 7 | – | ≤ 7 | – | ≤ 7 | – | ≤ 7 | – |

| 2 | 25~100 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | – | ≤ 10 | – | ≤ 10 | – | ≤ 10 | ||

| Backlash (Precision Class) | arcmin | 1 | 4~20 | ≤ 5 | ≤ 5 | – | ≤ 5 | – | ≤ 5 | – | ≤ 5 | – | ≤ 5 | – | ≤ 5 | – |

| 2 | 25~100 | ≤ 8 | ≤ 8 | ≤ 8 | ≤ 8 | ≤ 8 | ≤8 | ≤ 8 | – | ≤ 8 | – | ≤ 8 | – | ≤ 5 | ||

| Torsional Rigidity |

Nm/arcmin | 1,2 | 4~100 | 2 | 3 | 3 | 12 | 12 | 23 | 23 | 38 | 38 | 110 | 110 | 210 | 210 |

| Max. Bending moment Mmax (2) |

Nm | 1,2 | 4~100 | 41 | 123 | 123 | 241 | 241 | 417 | 417 | 247 | 247 | 719 | 719 | 1,188 | 1,188 |

| Max. Axial load Fa max (2) |

N | 1,2 | 4~100 | 1,050 | 2,140 | 2,140 | 2,750 | 2,750 | 5,230 | 5,230 | 6,370 | 6,370 | 9,880 | 9,880 | 12,830 | 12,830 |

| service life (2) |

hr | 1,2 | 4~100 | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 |

| Noise level (3) |

dB(A) | 1,2 | 4~100 | ≤ 61 | ≤ 63 | ≤ 63 | ≤ 65 | ≤ 65 | ≤ 68 | ≤ 68 | ≤ 70 | ≤ 70 | ≤ 72 | ≤ 72 | ≤ 74 | ≤ 74 |

| Weight | kg | 1 | 4~20 | 1.0 | 2.3 | – | 6.5 | – | 13.9 | – | 29 | – | 67.4 | – | 113 | – |

| 2 | 25~100 | 1.2 | 2.8 | 2.4 | 8.0 | 6.9 | 17.7 | 15.1 | – | 26.6 | – | 61.2 | – | 113.5 | ||

| Mass Moments of inertia (4) |

kg cm2 | 1 | 4~20 | 0.04 | 0.15 | – | 0.8 | – | 2.8 | – | 11.9 | – | 23.5 | – | 54 | – |

| 2 | 25~100 | 0.03 | 0.07 | 0.07 | 0.5 | 0.5 | 1.5 | 1.5 | – | 5.1 | – | 8.03 | – | 23.5 | ||

| Operating Temp. (5) |

℃ | 1,2 | 4~100 | -10 ~ +90 | ||||||||||||

| Lubrication | – | 1,2 | 4~100 | High temperature & Extreme pressure grease | ||||||||||||

| Mounting position |

– | 1,2 | 4~100 | All directions | ||||||||||||

| Efficiency η |

% | 1 | 4~20 | ≥ 95 | ||||||||||||

| 2 | 25~100 | ≥ 92 | ||||||||||||||

| Degree of protection |

– | 1,2 | 4~100 | IP 65 | ||||||||||||