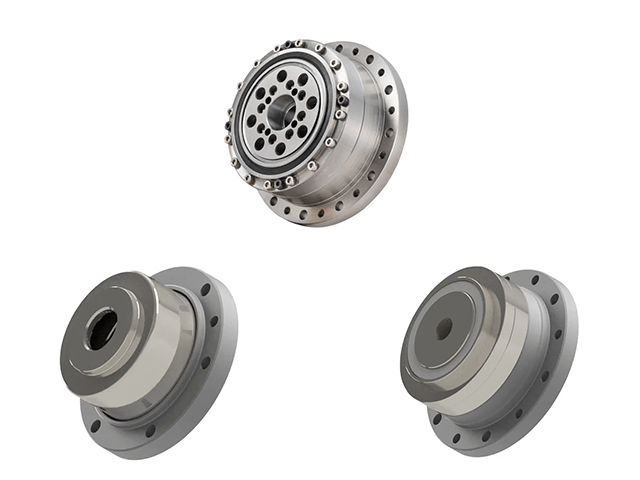

Precision Reducers

SH SERIES

- 低バックラッシ

- 高い位置精度と高精度再現性

- コンパクトなデザイン

- 高トルク

- 静かな動作

- 低メンテナンス

APPLICATION AREAS

- ロボット工学

- ファクトリーオートメーション

- 航空宇宙

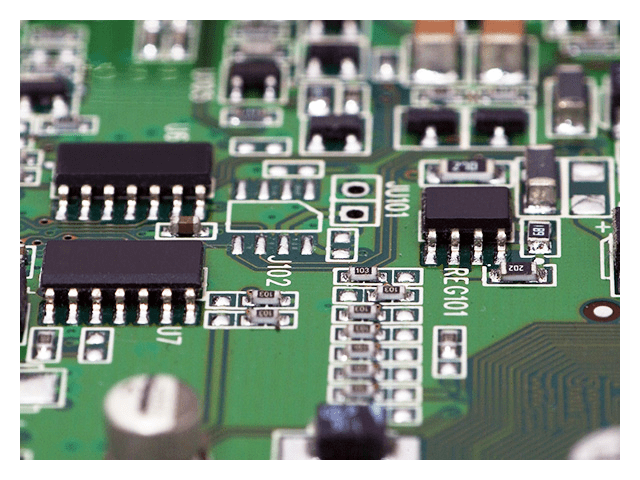

- 半導体

- 医学

- 光学機械

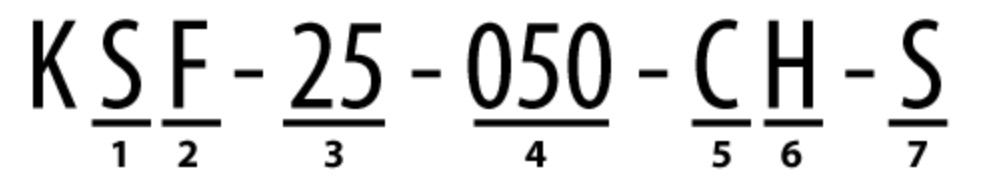

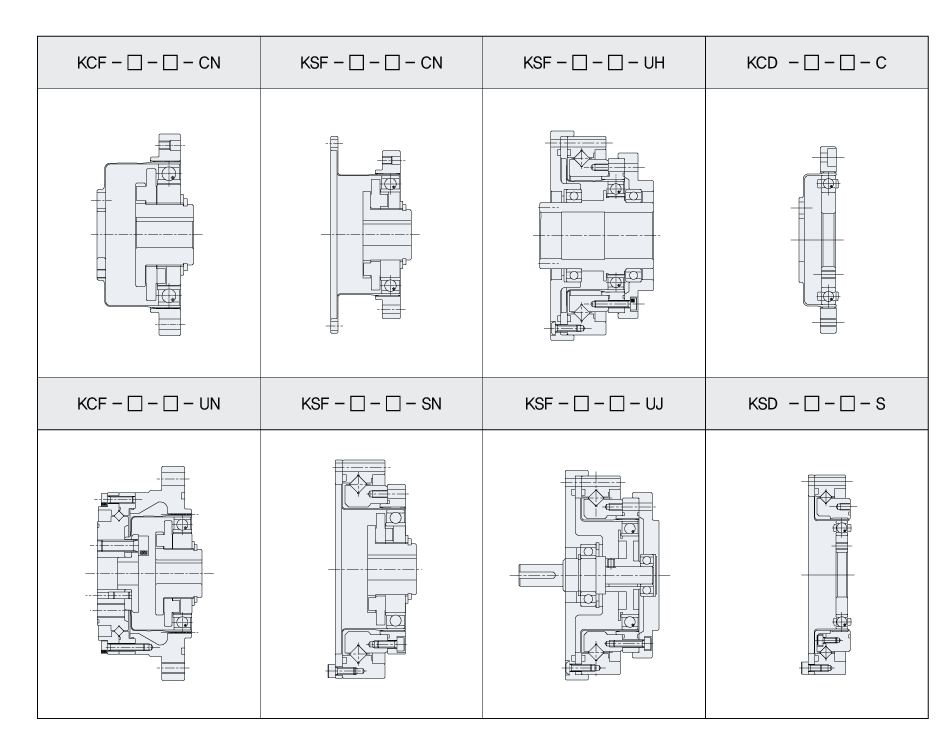

| 1 | Series Name | C: Cup type S: Silk hat |

| 2 | Torque | F: Normal G: High torque D: Compact |

| 3 | Number | 14 17 20 25 32 |

| 4 | Ratio | 050: 1/50 080: 1/80 100: 1/100 120: 1/120 160: 1/60 |

| 5 | Type | C: Component U: Unit S: Simple unit |

| 6 | Input option | H: Hollow J: Input shaft N: Normal |

| 7 | Special type |

Coding example

Specifications

Component Cup Type

| No. | 14 | 17 | 20 | 25 | 32 | ||||||||||||||

| Ratio | 50 | 80 | 100 | 50 | 80 | 100 | 120 | 50 | 80 | 100 | 120 | 50 | 80 | 100 | 120 | 50 | 80 | 100 | 120 |

| Rated torque | 7 | 9 | 9 | 21 | 26 | 28 | 28 | 33 | 40 | 47 | 47 | 51 | 66 | 70 | 70 | 89 | 122 | 142 | 142 |

| Allowable torque | 23 | 27 | 32 | 44 | 50 | 63 | 63 | 73 | 83 | 96 | 96 | 127 | 142 | 163 | 163 | 253 | 316 | 346 | 346 |

| Maximum torque | 46 | 55 | 63 | 91 | 101 | 129 | 129 | 127 | 149 | 172 | 172 | 242 | 266 | 295 | 295 | 447 | 590 | 673 | 673 |

| Transmission angular accuracy |

2.0 | 1.5 | 1.5 | 2.0 | 1.5 | 1.5 | 1.5 | 1.5 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Hysteresis loss | 2.0 | 1.5 | 1.5 | 2.0 | 1.5 | 1.5 | 1.5 | 2.0 | 1.0 | 1.0 | 1.0 | 2.0 | 1.0 | 1.0 | 1.0 | 2.0 | 1.0 | 1.0 | 1.0 |

| Rated input rotational speed (rpm) |

3,000 | 3,000 | 3,000 | 3,000 | 3,000 | ||||||||||||||

| Permissible max. input rotational speed |

8,500 | 7,300 | 6,500 | 5,600 | 4,800 | ||||||||||||||

| Inertia moment (x10-4kgm2) |

0.038 | 0.085 | 0.207 | 0.544 | 1.630 | ||||||||||||||

| Weight (kg) | 0.10 | 0.20 | 0.26 | 2.43 | 0.91 | ||||||||||||||

Unit Cup Type

| No. | 14 | 17 | 20 | 25 | 32 | ||||||||||||||

| Ratio | 50 | 80 | 100 | 50 | 80 | 100 | 120 | 50 | 80 | 100 | 120 | 50 | 80 | 100 | 120 | 50 | 80 | 100 | 120 |

| Rated torque | 7 | 9 | 9 | 21 | 26 | 28 | 28 | 33 | 40 | 47 | 47 | 51 | 66 | 70 | 70 | 89 | 122 | 142 | 142 |

| Allowable torque | 23 | 27 | 32 | 44 | 50 | 63 | 63 | 73 | 83 | 96 | 96 | 127 | 142 | 163 | 163 | 253 | 316 | 346 | 346 |

| Maximum torque | 46 | 55 | 63 | 91 | 101 | 129 | 129 | 127 | 149 | 172 | 172 | 242 | 266 | 295 | 295 | 447 | 590 | 673 | 673 |

| Transmission angular accuracy |

2.0 | 1.5 | 1.5 | 2.0 | 1.5 | 1.5 | 1.5 | 1.5 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Hysteresis loss | 2.0 | 1.5 | 1.5 | 2.0 | 1.5 | 1.5 | 1.5 | 2.0 | 1.0 | 1.0 | 1.0 | 2.0 | 1.0 | 1.0 | 1.0 | 2.0 | 1.0 | 1.0 | 1.0 |

| Rated input rotational speed (rpm) |

3,000 | 3,000 | 3,000 | 3,000 | 3,000 | ||||||||||||||

| Permissible max. input rotational speed |

8,500 | 7,300 | 6,500 | 5,600 | 4,800 | ||||||||||||||

| Inertia moment (x10-4kgm2) |

0.037 | 0.085 | 0.207 | 0.544 | 1.630 | ||||||||||||||

| Weight (kg) | 0.50 | 0.68 | 0.95 | 1.5 | 3.3 | ||||||||||||||

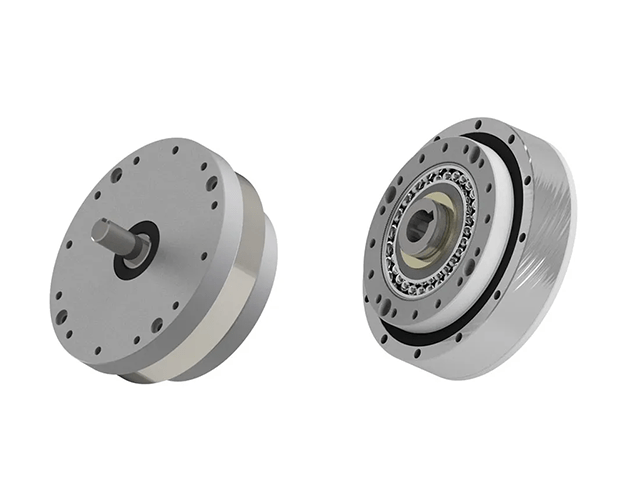

Unit Silk Hat Hollow Shaft Type

| No. | 14 | 17 | 20 | 25 | 32 | ||||||||||||||

| Ratio | 50 | 80 | 100 | 50 | 80 | 100 | 120 | 50 | 80 | 100 | 120 | 50 | 80 | 100 | 120 | 50 | 80 | 100 | 120 |

| Rated torque | 7 | 9 | 9 | 21 | 26 | 28 | 28 | 33 | 40 | 47 | 47 | 51 | 66 | 70 | 70 | 89 | 122 | 142 | 142 |

| Allowable torque | 23 | 27 | 32 | 44 | 50 | 63 | 63 | 73 | 83 | 96 | 96 | 127 | 142 | 163 | 163 | 253 | 316 | 346 | 346 |

| Maximum torque | 46 | 55 | 63 | 91 | 101 | 129 | 129 | 127 | 149 | 172 | 172 | 242 | 266 | 295 | 295 | 447 | 590 | 673 | 673 |

| Transmission angular accuracy |

2.0 | 1.5 | 1.5 | 2.0 | 1.5 | 1.5 | 1.5 | 1.5 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Hysteresis loss | 2.0 | 1.5 | 1.5 | 2.0 | 1.5 | 1.5 | 1.5 | 2.0 | 1.0 | 1.0 | 1.0 | 2.0 | 1.0 | 1.0 | 1.0 | 2.0 | 1.0 | 1.0 | 1.0 |

| Rated input rotational speed (rpm) |

3,000 | 3,000 | 3,000 | 3,000 | 3,000 | ||||||||||||||

| Permissible max. input rotational speed |

8,500 | 7,300 | 6,500 | 5,600 | 4,800 | ||||||||||||||

| Inertia moment (x10-4kgm2) |

0.103 | 0.230 | 0.460 | 1.240 | 3.180 | ||||||||||||||

| Weight (kg) | 0.57 | 0.79 | 1.1 | 1.7 | 3.4 | ||||||||||||||

Simple Unit Silk Hat Type

| No. | 14 | 17 | 20 | 25 | 32 | ||||||||||||||

| Ratio | 50 | 80 | 100 | 50 | 80 | 100 | 120 | 50 | 80 | 100 | 120 | 50 | 80 | 100 | 120 | 50 | 80 | 100 | 120 |

| Rated torque | 7 | 9 | 9 | 21 | 26 | 28 | 28 | 33 | 40 | 47 | 47 | 51 | 66 | 70 | 70 | 89 | 122 | 142 | 142 |

| Allowable torque | 23 | 27 | 32 | 44 | 50 | 63 | 63 | 73 | 83 | 96 | 96 | 127 | 142 | 163 | 163 | 253 | 316 | 346 | 346 |

| Maximum torque | 46 | 55 | 63 | 91 | 101 | 129 | 129 | 127 | 149 | 172 | 172 | 242 | 266 | 295 | 295 | 447 | 590 | 673 | 673 |

| Transmission

angular accuracy |

2.0 | 1.5 | 1.5 | 2.0 | 1.5 | 1.5 | 1.5 | 1.5 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Hysteresis loss | 2.0 | 1.5 | 1.5 | 2.0 | 1.5 | 1.5 | 1.5 | 2.0 | 1.0 | 1.0 | 1.0 | 2.0 | 1.0 | 1.0 | 1.0 | 2.0 | 1.0 | 1.0 | 1.0 |

| Rated input

rotational speed (rpm) |

3,000 | 3,000 | 3,000 | 3,000 | 3,000 | ||||||||||||||

| Permissible max.

input rotational speed |

8,500 | 7,300 | 6,500 | 5,600 | 4,800 | ||||||||||||||

| Inertia moment

(x10-4kgm2) |

0.039 | 0.087 | 0.209 | 0.549 | 1.650 | ||||||||||||||

| Weight (kg) | 0.39 | 0.55 | 0.79 | 1.3 | 2.7 | ||||||||||||||

Unit Silk Hat Shaft Input Type

| No. | 14 | 17 | 20 | 25 | 32 | ||||||||||||||

| Ratio | 50 | 80 | 100 | 50 | 80 | 100 | 120 | 50 | 80 | 100 | 120 | 50 | 80 | 100 | 120 | 50 | 80 | 100 | 120 |

| Rated torque | 7 | 9 | 9 | 21 | 26 | 28 | 28 | 33 | 40 | 47 | 47 | 51 | 66 | 70 | 70 | 89 | 122 | 142 | 142 |

| Allowable torque | 23 | 27 | 32 | 44 | 50 | 63 | 63 | 73 | 83 | 96 | 96 | 127 | 142 | 163 | 163 | 253 | 316 | 346 | 346 |

| Maximum torque | 46 | 55 | 63 | 91 | 101 | 129 | 129 | 127 | 149 | 172 | 172 | 242 | 266 | 295 | 295 | 447 | 590 | 673 | 673 |

| Transmission angular accuracy |

2.0 | 1.5 | 1.5 | 2.0 | 1.5 | 1.5 | 1.5 | 1.5 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Hysteresis loss | 2.0 | 1.5 | 1.5 | 2.0 | 1.5 | 1.5 | 1.5 | 2.0 | 1.0 | 1.0 | 1.0 | 2.0 | 1.0 | 1.0 | 1.0 | 2.0 | 1.0 | 1.0 | 1.0 |

| Rated input rotational speed (rpm) |

3,000 | 3,000 | 3,000 | 3,000 | 3,000 | ||||||||||||||

| Permissible max. input rotational speed |

8,500 | 7,300 | 6,500 | 5,600 | 4,800 | ||||||||||||||

| Inertia moment (x10-4kgm2) |

0.037 | 0.089 | 0.208 | 0.554 | 1.740 | ||||||||||||||

| Weight (kg) | 0.48 | 0.69 | 1.0 | 1.6 | 3.2 | ||||||||||||||

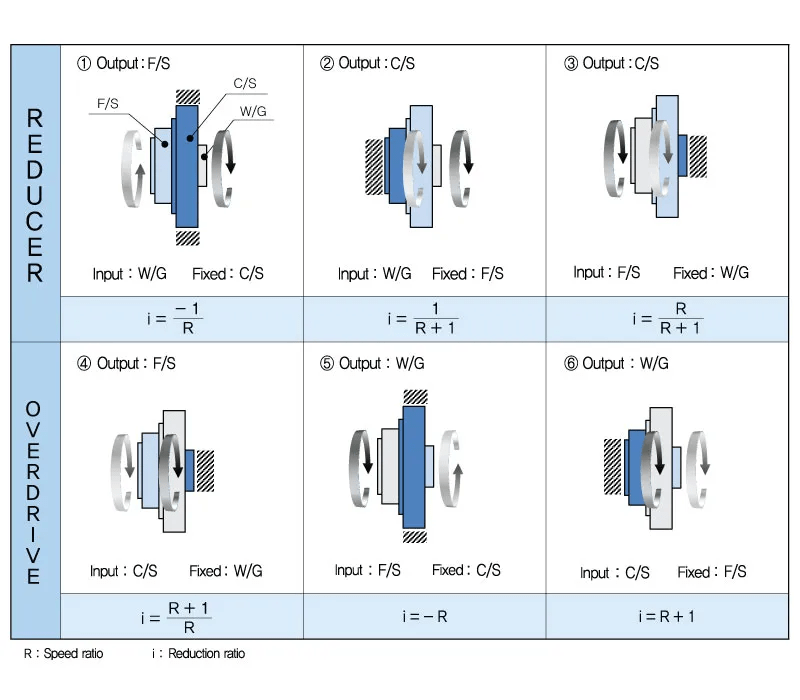

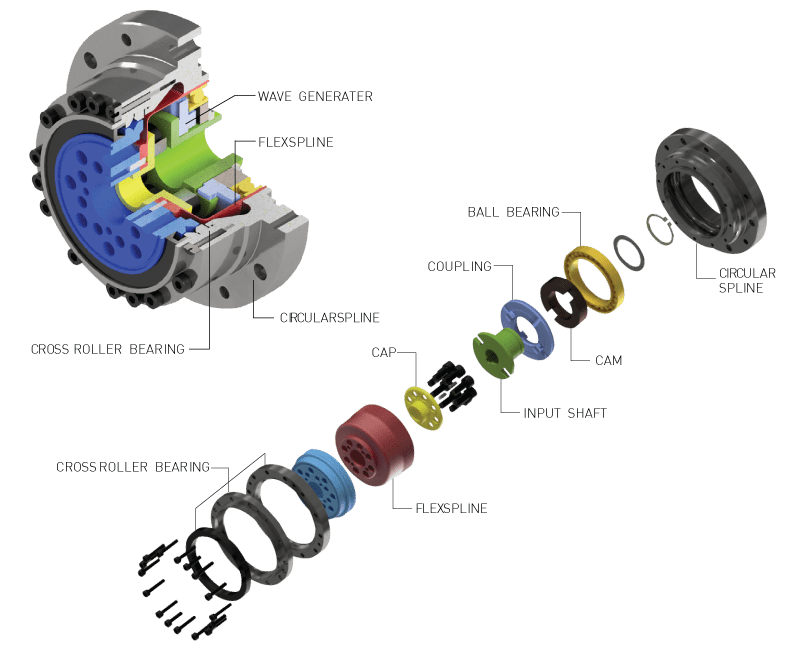

Build

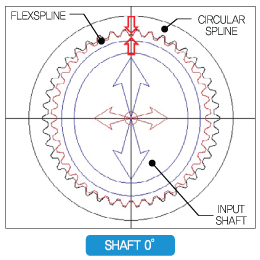

Operating principle

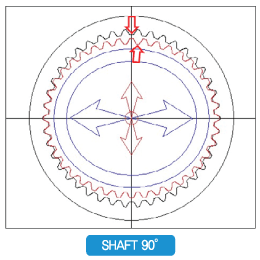

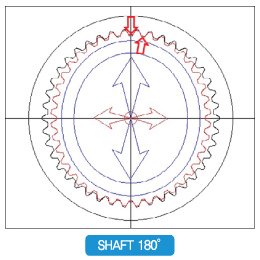

フレックススプラインの歯は上下でC/Sの歯と噛み合い、左右では完全に分離されています。

INPUT SHAFTを左(CCW)に回すとF/Sが弾性変形しC/Sの歯と噛み合い右(CW)に移動します。

C/Sが180°CCW方向に回転すると、F/Sの1歯がCW方向に移動します。

Rotation direction and reduction ratio